Used Pallet Racks

Tens of Thousands of Used Pallet Rack Items In-Stock.

Low Cost Shipping To Almost Anywhere.

Tens of Thousands of Used Pallet Rack Items In-Stock.

Low Cost Shipping To Almost Anywhere.

$29.20

$29.20

$41.50

$41.50

$22.85

$22.85

$21.61

$21.61

$22.51

$22.51

$22.46

$22.46

Teardrop Pallet Rack Beams

Pallet racks improve the efficiency of warehouse operations by enabling more effective use of available space. Warehouse pallet racking helps warehouse managers make better use of vertical space because they can store materials on high shelves without risk. Pallet racking also makes warehouses neater, which improves efficiency and helps to prevent misplaced goods. Consistent use of racks for storage increases pick and put away time and improves the flexibility of existing space.

The only drawback to warehouse pallet racking is the high cost of buying new. That’s why many savvy warehouse operators buy used pallet racks.

Some warehouse operations have used pallet racking for sale. They may sell used pallet racks when they reduce space or close a warehouse. However, it is not a good idea to buy used pallet racking directly from the warehouse, because you cannot be sure of quality and fair pricing.

Most warehouse pallet racking is made of steel, which has a long life, so there is no risk in buying used pallet racks as long as you can be certain the racks have not been exposed to moisture, which can cause rust.

Rust reduces the strength and utility of pallet racking. If there is even a little bit of rust, it is likely to spread. This not only reduces the appearance of your warehouse pallet racking, it can damage the structural integrity.

Buying Guide for Used Pallet Racks

Used pallet racks, also known as steel racks, warehouse racks, and industrial storage racks, are a common sight in any warehouse or storage setting because, as their name suggests, they are used for storing pallets loaded with products. There are a number of different styles of pallet racks. Both new and used pallet rack systems come in many different sizes and capacities so that they can accommodate a wide range of pallet sizes and load weights.

Below, you’ll find descriptions of the four most common types and two common styles of pallet rack systems. You may also want to check out our page on How to Build Your Pallet Racking System.

MHE Has the Variety You Need

We carry large lot sizes of a variety of used pallet racking.

Some examples include:

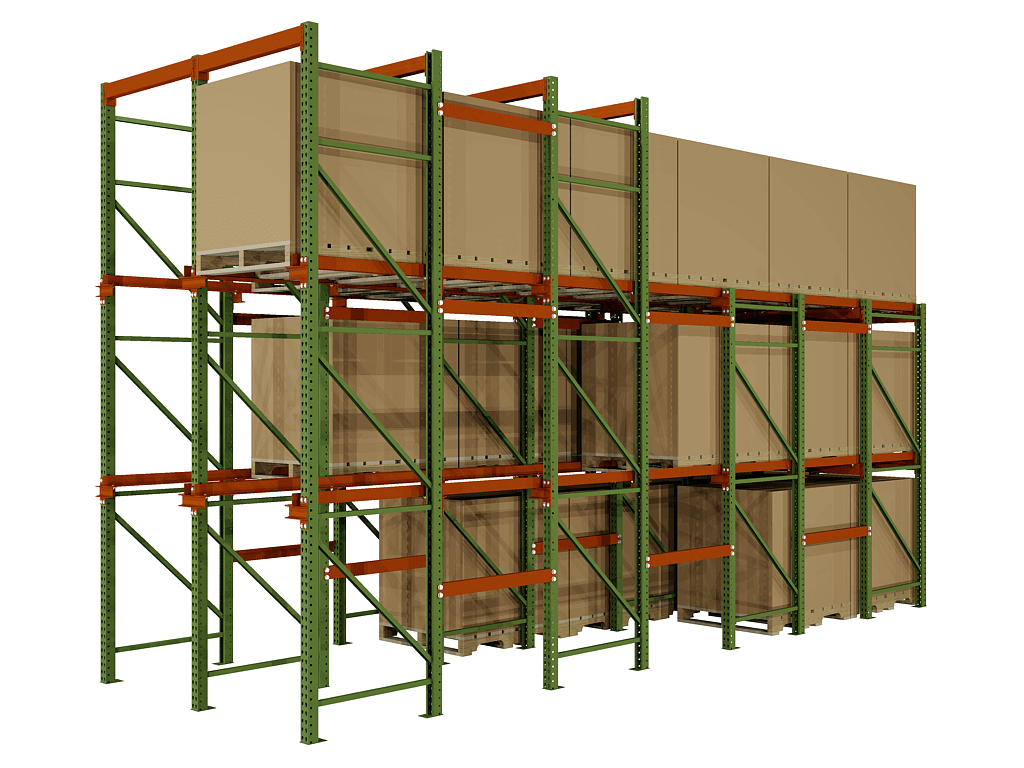

Selective Pallet Racks

Selective pallet racking systems are the most common style of pallet racks on the market today. Their basic components are upright frames and rack beams. With selective pallet racks, all of your products are easily accessible from your forklift travel aisles, and you don’t have to move other products around to gain access. This saves both time and money. Additionally, each selective pallet rack bay can have multiple beam levels. Selective pallet racks are great for storing a wide variety of products that you need immediate access to at any given time.

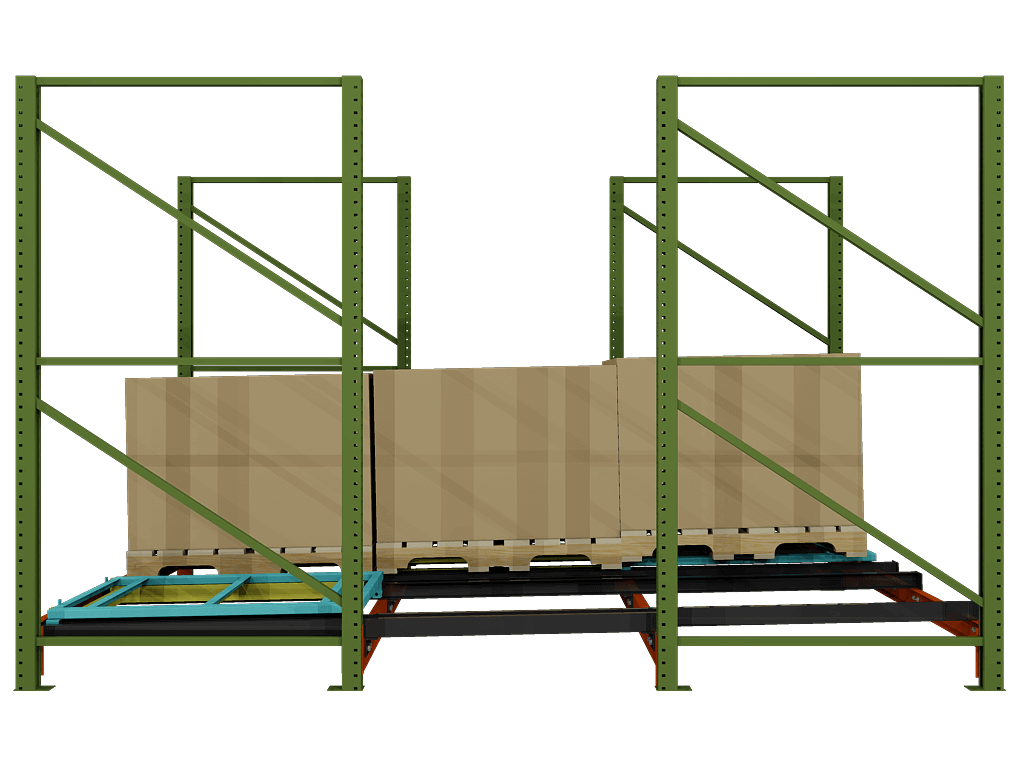

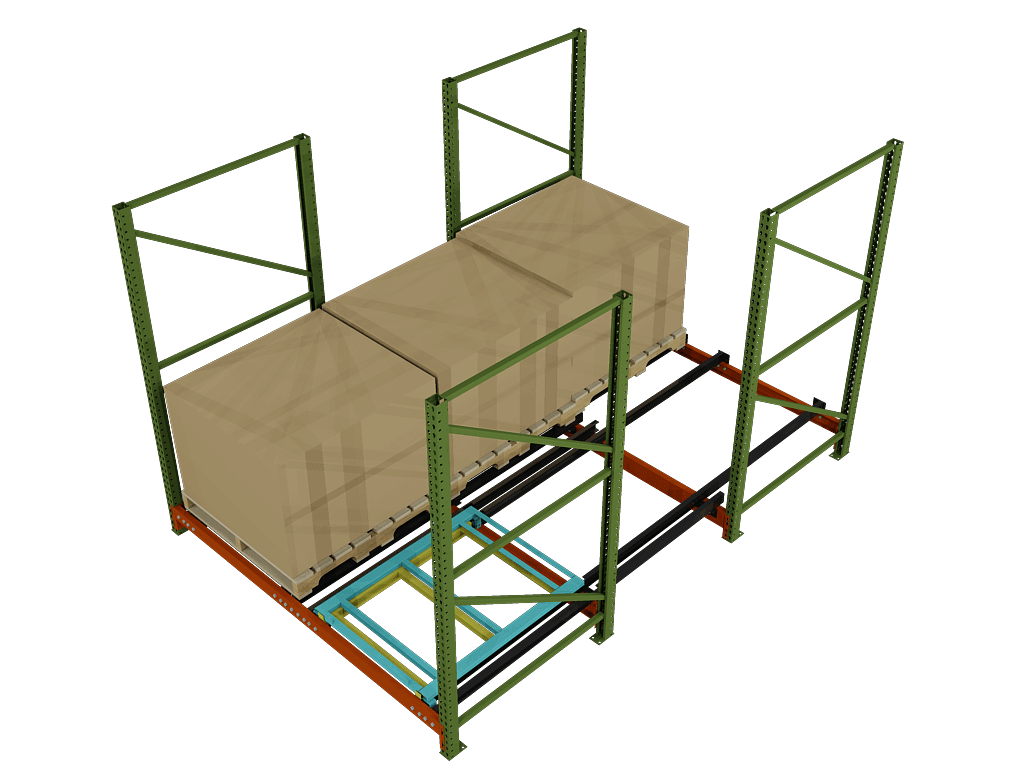

Pushback Pallet Racks

Pushback pallet racking systems are great when you store a lot of the same products. A new or used pushback pallet rack system allows you to store your products 2-6 pallet positions deep. If you place pushback racks back-to-back, you can achieve up to 12 deep bulk pallet storage in your warehouse. This ability limits the number of forklift travel aisles needed in your warehouse and gains you 25%-65% more storage capacity in the same area. Pushback storage systems should be used for Last-In/First-Out (LIFO) inventory management.

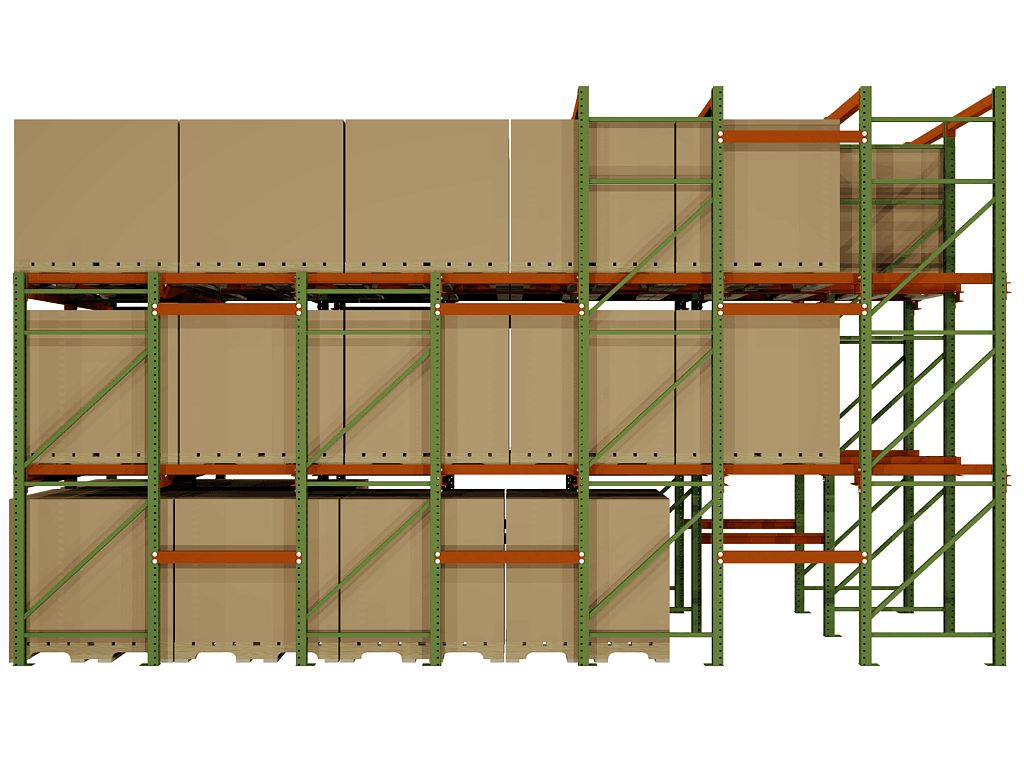

3-Deep Side View

3-Deep Arial View

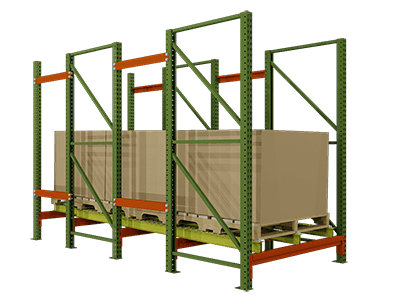

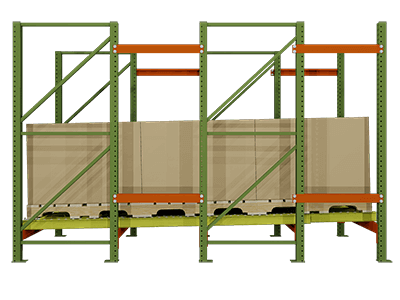

Pallet Flow Pallet Racks

Used pallet flow racks is another racking system that maximizes the use of your warehouse space. Like the pushback systems, pallet flow racking is a high-density storage option (2-6 pallet positions deep) with fewer forklift aisles. This warehouse rack style is driven by gravity and can be used for fast-moving product with First-In/First-Out (FIFO) stock rotation. Their sloped shelves have heavy-duty skate wheels that allow palletized loads to flow forward to a picking position. These steel racks can also be combined with carton flow systems that use multi-level picking modules to split loads into boxes or piece parts.

3 Deep Angle View

3 Deep Side View

Drive-In & Drive-Thru Pallet Racks

With drive-in and drive-through racking, density is the operative word. You can get up to 75% more pallet storage in the same space as with selective pallet racks. These steel racks maximize your available space, but they do require a lift truck. Drive-in and drive-through racks are best used for warehouse storage when you need a lot of storage density but don’t have a lot of variety. Drive-in racks are best suited for Last-In/First-Out (LIFO) inventory management and drive-through racks are best suited for First-In/First-Out (FIFO) stock rotation because they are accessible from either end.

6 Deep Angle View

6 Deep Side View

Pallet Rack Styles

When purchasing used pallet racks, it’s important to remember that flexibility is the key to getting the most out of your storage system.

Teardrop Pallet Racking

When possible, teardrop pallet racking systems are the way to go. They are one of the most popular styles available, largely because their unique design requires no bolts, nuts, clips, or other accessories in the assembly process. You know what that means: simple and fast assembly! Teardrop is a style, not a brand, so you can often mix and match teardrop pallet rack components from different brands without compromising your system.

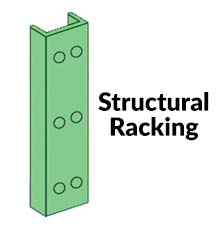

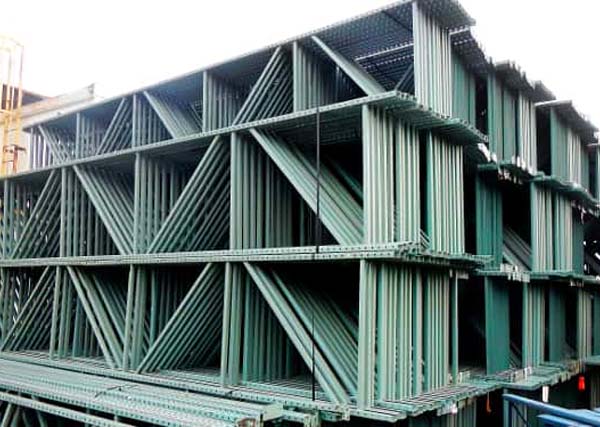

Structural Pallet Racks

Like teardrop pallet racks, structural pallet racks is a style rather than a brand. Pallet racks made in this style are made of heavy duty materials and held together with nuts and bolts. As a result, a professional installation team should be contracted to set up structural pallet racking systems. Because of their impact resistance, this style of warehouse racks tend to be very popular in areas with seismic activity.

M-H-E Equipment Condition Guide

Used pallet racks, also known as steel racks, warehouse racks, and industrial storage racks, are a common sight in any warehouse or storage setting because, as their name suggests, they are used for storing pallets loaded with products. There are a number of different styles of pallet racks. Both new and used pallet rack systems come in many different sizes and capacities so that they can accommodate a wide range of pallet sizes and load weights.

Material Handling Exchange sells pallet racks and other industrial storage racks in any of the following conditions:

Used/As-Is Equipment

Our used/as-is equipment is your most economic choice for buying equipment. We vouch for the structural integrity of all used equipment we sell, but these racking systems have not been repainted or prepped in any way. Which means that they may have markings from their previous use.

Refurbished Equipment

All stickers and markings are removed from the surface of the equipment.Each component is inspected thoroughly for structural damage – if any damage is found, it is repaired or replaced as needed. The equipment is cleaned and prepped for painting using the latest technology to remove any rust or residue without affecting the integrity or value of the metal. The item is then painted and cured. The equipment is cooled and is then sorted, packaged, and shipped to the client.

Buy From the Industry Leader

Material Handling Exchange specializes in buying and selling used warehouse pallet racking. We know how to judge quality and we understand fair pricing based on the condition of the used pallet racks. In addition, we can consolidate lots of used pallet racking so that you can buy enough of the same style pallet racks to outfit your entire warehouse. This gives you the peace of mind that comes from knowing you got a great deal on superior quality used pallet racking. You will be able to enjoy all the benefits of warehouse pallet racking at rock-bottom prices.

You wouldn’t go to the second-best supplier for any critical component of your product. Why would you consider going to the second-best supplier of used warehouse pallet racking? Material Handling Exchange offers the widest selection and the best prices on any quantity and style of used pallet racking, and we deliver anywhere in the country.

We have in-house experts who can advise you on the right type of warehouse pallet racking for your needs. In addition, we buy and sell higher volumes of used pallet racks than our competitors, so you know you are getting a great price, high quality and the ability to add more racks of the same style later.

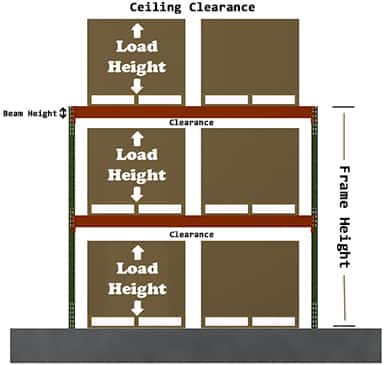

How to Build Pallet Racking

Our trained sales people at MHE want to make designing the right pallet rack system for your operation as painless as possible. The information below details what you need to know for purchasing the right pallet racks the first time. If you need help in purchasing your pallet racks please don’t hesitate to give us a call.

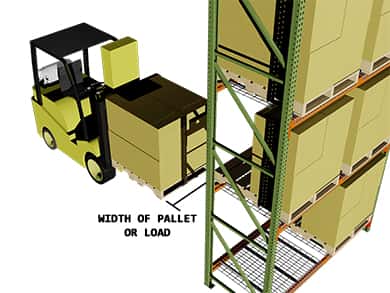

Counter Balanced Forklifts

A Counter Balanced type forklift can be one you walk behind or one the Operator sits down. A counter balance lift , particularly the sit down type generally operates best in a minimum travel aisle width of 12 feet.

Standard Outrigger or Straddle Outrigger Forklifts

Stand-up Narrow Aisle Forklifts are with outriggers typically work best in a minimum travel aisle width of 10 foot 6 inches.

Building Pallet Racking Scenario

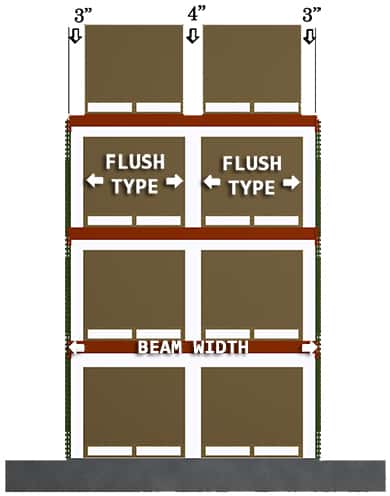

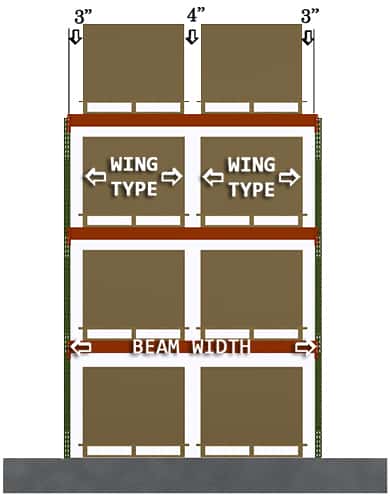

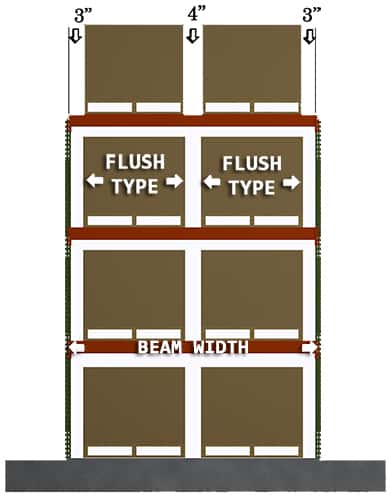

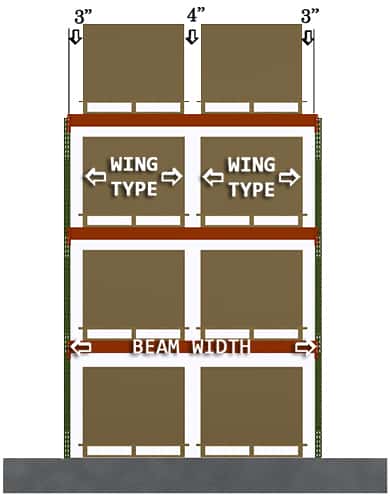

In this example you will see a total of 10” of additional storage space for a Two (2) pallet configuration. If you are using a 3 pallet configuration you will have 14” of additional storage space. If for example your standard pallets are 40” wide and the product does not overhang the 40” width of the pallet, then you could chose a 90” long beam for your application. It is important to note that in order to give you flexibility, in a case where some of your pallets will or could have overhang, may we suggest a 96” long beam or a 144” long beam for a 3 pallet wide configuration. These are the most common size pallet rack beams used in storage applications today.

Flush Type

Wing Type

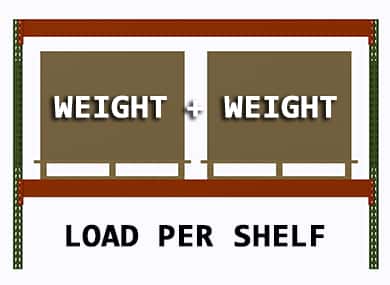

How To Determine The Correct Pallet Rack Beam Capacity

Simply take the number of pallets you will be storing per beam level Multiplied by the maximum load weight of each pallet to achieve The required beam capacity “per pair” of pallet rack beams. Example: 2500Lb Pallet weight x 2 pallets=5000lbs. You would need a beam rated at 5000lbs or More per pair of beams.

In a case where you are only going to have one beam level in your pallet Rack bay it is important to decrease the beam capacity by 15% to account for the reduced end fixity while Using only heavier beams 5 ½” face or greater which have a four hook connector late.

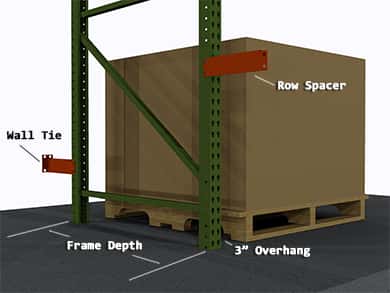

How To Determine The Correct Pallet Rack Upright Frame Depth and the appropriate Wall Tie or Row Spacer

Don't see what you're looking for?

Chances are we have it in stock today and can ship it immediately!

What Our Customers Are Saying

Past Customers

Our Affiliate Companies