Wire Decks

Thousands of New & Used Wire Decking in-stock for Immediate shipment to your door!

When it comes to buying new pallet racking systems, it's important to know the type of decking to use.

Thousands of New & Used Wire Decking in-stock for Immediate shipment to your door!

When it comes to buying new pallet racking systems, it's important to know the type of decking to use.

$16.22 – $22.07

Select options

This product has multiple variants. The options may be chosen on the product page

$16.22 – $22.07

Select options

This product has multiple variants. The options may be chosen on the product page

$18.23 – $23.69

Select options

This product has multiple variants. The options may be chosen on the product page

$18.23 – $23.69

Select options

This product has multiple variants. The options may be chosen on the product page

$23.45 – $27.09

Select options

This product has multiple variants. The options may be chosen on the product page

$23.45 – $27.09

Select options

This product has multiple variants. The options may be chosen on the product page

$16.40 – $25.31

Select options

This product has multiple variants. The options may be chosen on the product page

$16.40 – $25.31

Select options

This product has multiple variants. The options may be chosen on the product page

$12.18

$12.18

$12.18

$12.18

One major advantage that mesh wire decking has over solid metal or wood decking is that it allows more light to filter down, so it is easier to read labels and tags on pallets, reducing errors. In addition, the openings in mesh wire decking enable more effective sprinkler system access. In the event of a fire, this may help lessen damage to stored goods and reduce losses.

It’s important to get mesh wire decking that is strong enough to safely store the materials in your stock room. The wrong mesh wire decking may buckle or slip if it isn’t strong enough to support your goods. This is a safety hazard as well as a potential loss of materials, so it is best to work with a company that fully understands the warehousing industry and takes the time to learn about the materials you need to store.

At Material Handling Exchange our experienced team is eager to discuss your warehousing needs, and we have a wide variety of new and used wire decking for sale. This way, you can be certain you are getting the right quality mesh wire decking for your warehouse.

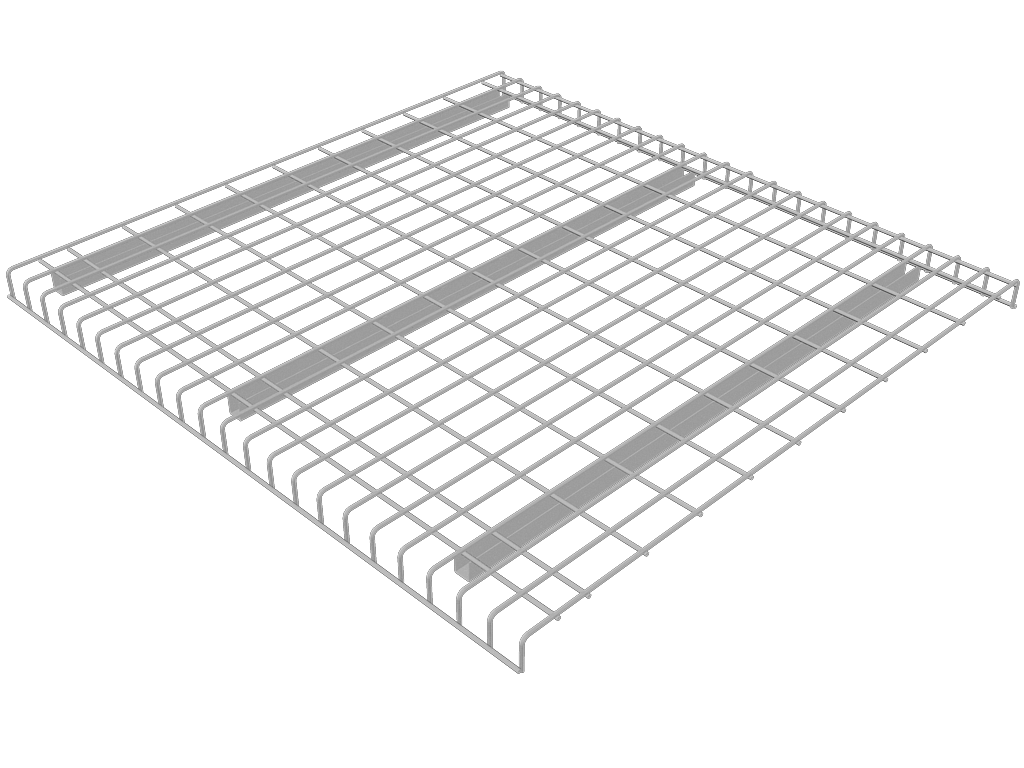

Flat and Waterfall Wire Decking

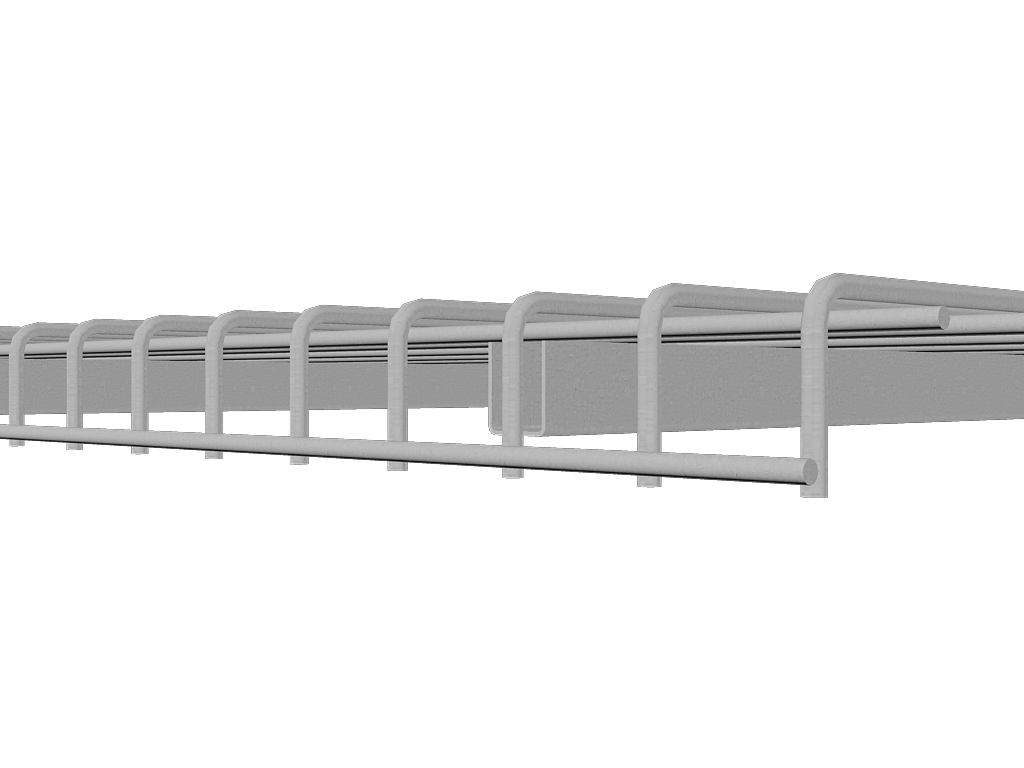

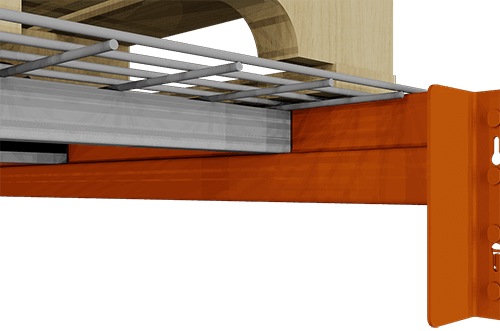

Some mesh wire decking lies flat on the support beams, while waterfall wire decking has a lip extending over the front and rear rails to add extra support. Waterfall wire decking is an excellent choice for adding extra rigidity for heavy loads. Either type of decking may have additional rails to add strength.

Mesh wire decking consists of heavy gauge steel arranged in a grid pattern. Grid sizes may vary, but most use a grid that is 2 ½” by 4”. Another advantage of wire mesh decking is that it is easy to assemble. It simply sits on top of the support beams and requires no additional fasteners.

New vs. Used

Mesh wire decking is usually coated with a gray enamel finish to create a uniform appearance and to protect the mesh from the inevitable dings and scratches that occur in a busy warehouse. Used wire mesh decking may have a worn appearance with chips that expose the steel. Once the enamel coating chips, the decking is more susceptible to rust.

As long as it has not been stored outside, it may not matter whether you select new or used decking. When exposed to rain or wet weather, the steel in the wire mesh decking can start to rust, but otherwise, new and used wire decking are equally strong and can have a long life.

New wire mesh decking has the advantage of a fresh, uniform appearance. You may want to buy new decking if you are setting up a new warehouse or expanding your space.

How to Select Your Wire Decking

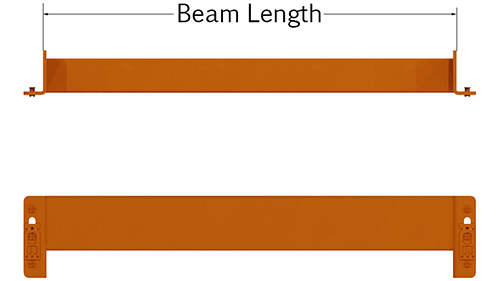

Determine the beam length measurement that the decks are going to be installed on by measuring the inside edge of the beam connector where it would sit flush with the side of the upright frame. Note that you want to use the measurement that is similar to your desired pallet racking bay widths. Example: A 96” beam will have a measurement from the inside edges of the beam connectors that is generally within 1/16” or so of what the desired bay dimension is. You do not want to measure between the furthest outside edges of the beam connectors or the measurement will be too long.

Find Your Beam Length

Deck Width Chart

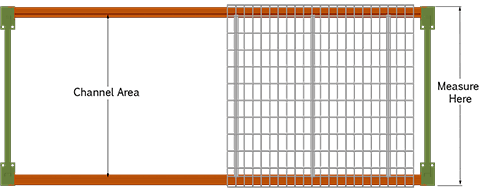

Next, Determine The Upright Depth

Example: 42” deep upright would require a wire mesh deck that is 42” Deep. · If you are ordering wire decks to go with your existing pallet rack uprights, then you will need confirm that the measurement between the steps of your existing pallet rack beams will accommodate a channel lengths of the new decks.

Find Your Beam Depth

Deck Width Chart

Don't see what you're looking for?

Chances are we have it in stock today and can ship it immediately!

What Our Customers Are Saying

Past Customers

Our Affiliate Companies